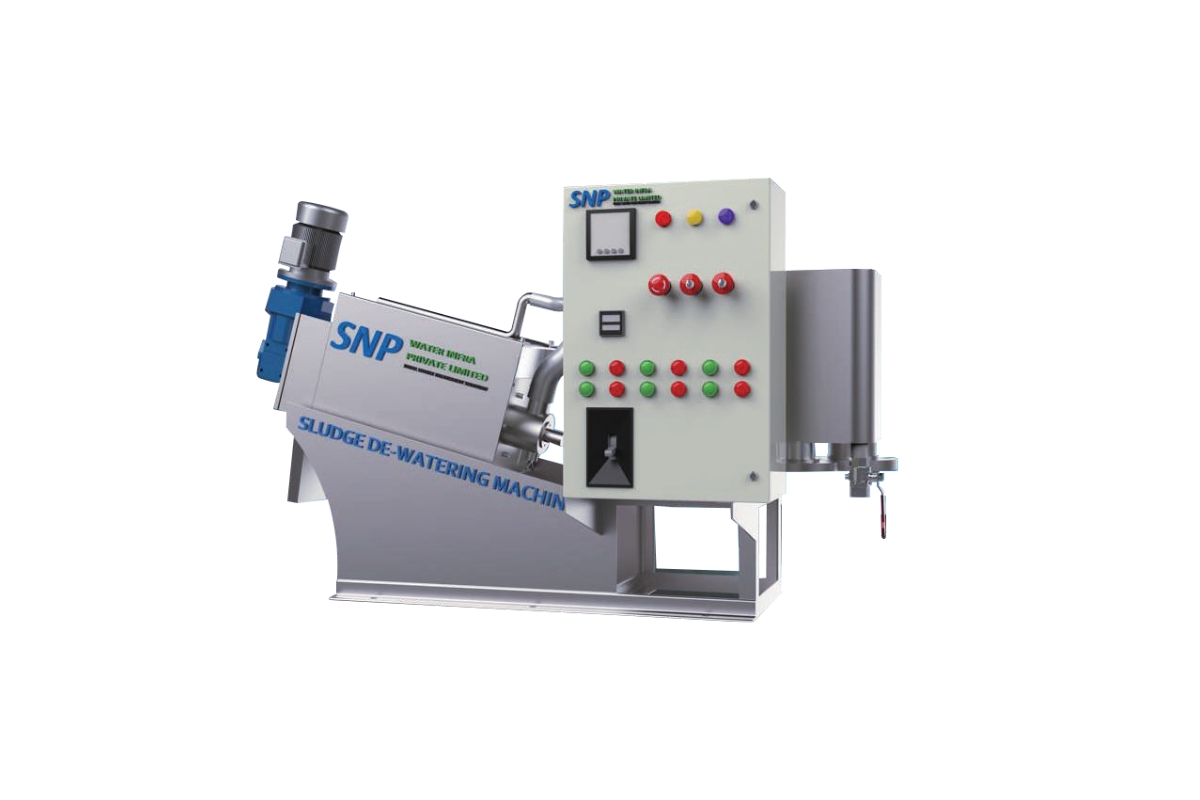

🔍 Key Features:

✅ Energy-Efficient Operation

Operates at low speed (less than 3 RPM), consuming up to 90% less energy than traditional centrifuge or belt presses.

✅ Self-Cleaning Design

Equipped with a movable ring and fixed ring structure that prevents clogging, ensuring continuous, maintenance-free operation.

✅ Fully Enclosed System

The sealed unit design ensures odor control and zero water spillage, making it ideal for indoor installations.

✅ Compact Footprint

Its space-saving design allows easy integration even in tight plant layouts or retrofit projects.

✅ Continuous and Automatic Operation

Can run 24/7 with minimal human intervention, including auto-start/stop and integrated PLC control.

✅ Multi-Sludge Capability

Capable of handling activated sludge, anaerobic sludge, and digested sludge from both municipal and industrial treatment processes.

📐 Technical Specifications:

-

Flow Capacity: 1 to 3000+ LPH (based on sludge concentration and type)

-

Sludge Concentration: 0.2% – 2% DS input

-

Final Output Cake: 18% – 25% DS (dry solids)

-

Power Consumption: 0.3 – 2.2 kW depending on model

-

Construction: SS304 / SS316L available

-

Control System: Fully automated with optional PLC & HMI panel

🏭 Applications:

-

Sewage Treatment Plants (STPs)

-

Effluent Treatment Plants (ETPs)

-

Food & Beverage Industries

-

Textile Dyeing Units

-

Pulp & Paper Mills

-

Pharmaceuticals & Chemicals

-

Slaughterhouses, Breweries, and More

🌱 Why Choose Infinity’s Screw Press?

-

✅ Lower energy costs

-

✅ Minimal operator involvement

-

✅ Reduced sludge disposal volume

-

✅ Odor-free and hygienic operation

-

✅ Long lifespan with stainless steel body

-

✅ Low noise and vibration

📞 Want to optimize your sludge handling process?

Reach out to Infinity Filtra Equipments for technical sizing, pilot testing, and turnkey solutions.

📧 info@infinityfiltraequipments.com

📱 +91 89258 90870

Reviews

There are no reviews yet.